In industrial environments, fans are not occasional-use equipment. They operate for long hours, often continuously, making them a silent but significant contributor to energy consumption. While many facilities attempt to reduce electricity costs by limiting usage hours, the real opportunity lies elsewhere—at the motor level.

Replacing conventional induction fans with BLDC (Brushless Direct Current) fans is increasingly being recognised as a strategic investment rather than a simple upgrade. When evaluated correctly, the return on investment (ROI) becomes clear, measurable, and compelling.

Why Conventional Fans Impact ROI Negatively

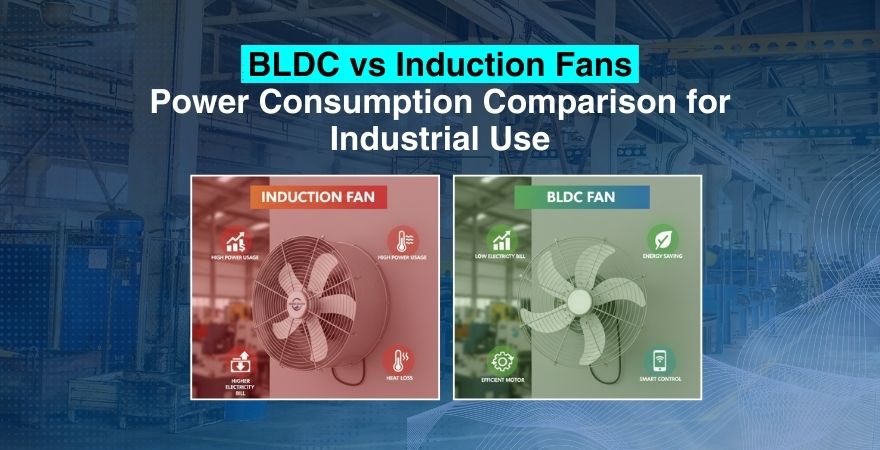

Induction motor fans consume higher power due to inherent electrical and mechanical losses. Over long operating hours, this inefficiency results in:

- Higher electricity bills

- Excess heat generation within the motor

- Increased maintenance and downtime

- Shorter operational lifespan

In industrial settings where fans run 12–24 hours a day, these inefficiencies accumulate rapidly, increasing total cost of ownership year after year.

How BLDC Fans Change the ROI Equation

BLDC technology fundamentally improves how electrical energy is converted into airflow. By using electronic commutation instead of brushes, BLDC motors minimise energy loss and heat generation.

This leads to three immediate ROI drivers:

- Lower power consumption during every hour of operation

- Reduced maintenance and service interventions

- Longer equipment life and higher operational reliability

Unlike usage-based savings, BLDC efficiency delivers returns every time the fan is switched ON.

Key Factors That Determine ROI When Switching to BLDC Fans

1. Energy Savings

BLDC fans typically consume 40–60% less power than conventional induction fans while delivering comparable airflow. Over thousands of operating hours annually, this translates into substantial cost savings.

2. Continuous-Duty Performance

Industrial fans rarely get downtime. BLDC fans are designed for continuous operation without overheating, ensuring consistent airflow and predictable energy usage.

3. Maintenance Reduction

With fewer wear components and lower internal heat, BLDC fans require significantly less maintenance. Reduced service calls and downtime directly improve ROI.

4. Equipment Longevity

Lower heat stress inside the motor extends product life. A longer replacement cycle improves capital efficiency and reduces recurring expenditure.

Airzon’s BLDC Advantage in ROI Calculation

Airzon’s BLDC fans are engineered specifically for industrial and commercial use, not adapted from residential products. This distinction is critical when calculating ROI.

Key Airzon USPs that strengthen ROI:

- All-metal construction with no plastic components, ensuring durability in harsh environments

- BLDC motors optimised for continuous industrial operation

- Lower internal heat generation, reducing coil failure risk

- Stable performance under voltage fluctuations

- Reduced maintenance and long service life

By eliminating plastic parts and focusing on industrial-grade design, Airzon ensures that efficiency gains are sustained over the product’s lifecycle.

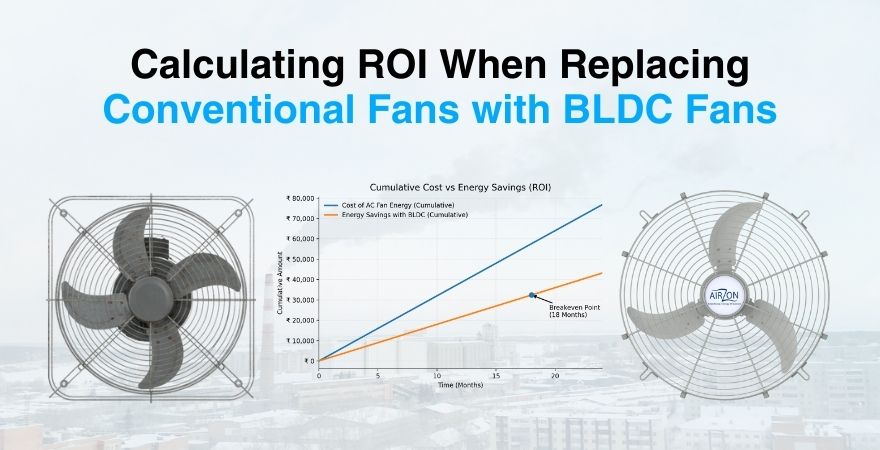

A Practical Way to Calculate ROI

A simple ROI evaluation considers:

- Operating hours per day

- Power consumption of existing induction fans

- Power consumption of BLDC replacements

- Electricity tariff

- Maintenance cost reduction

In most industrial applications, the energy savings alone recover the investment within 18–36 months. Beyond this payback period, the cost savings directly improve operational margins.

Why ROI Goes Beyond Numbers

Replacing conventional fans with BLDC fans is not only about reducing electricity bills. It also improves system reliability, lowers risk of unplanned downtime, enhances workplace comfort, and supports sustainability goals.

For industries focused on long-term efficiency, BLDC fans represent a measurable, low-risk upgrade with lasting impact.

Conclusion

Calculating ROI when replacing conventional fans with BLDC fans reveals a clear advantage. Lower power consumption, reduced maintenance, longer lifespan, and stable performance collectively deliver strong financial and operational returns.

With industrial-grade, plastic-free BLDC solutions, Airzon enables businesses to move beyond short-term cost cutting and adopt efficiency that pays back year after year.