At first glance, two industrial fans delivering the same airflow appear identical in performance. The space feels equally cool, air circulation seems consistent, and operations continue as usual. Yet, at the end of the month, the energy bills tell a very different story.

This difference often surprises facility managers and procurement teams. If airflow is the same, why does one fan cost significantly more to run than the other? The answer lies not in what you feel but in what happens inside the fan.

Airflow Is Only Half the Story

Airflow, usually measured in CMM, tells us how much air a fan moves. What it doesn’t tell us is how efficiently that air is produced.

Conventional induction fans and modern BLDC fans can be engineered to deliver similar airflow levels. The real difference lies in how much electrical power they consume to achieve it. Two fans may move the same volume of air, but one may be quietly wasting energy every hour it runs.

Where Energy Gets Lost

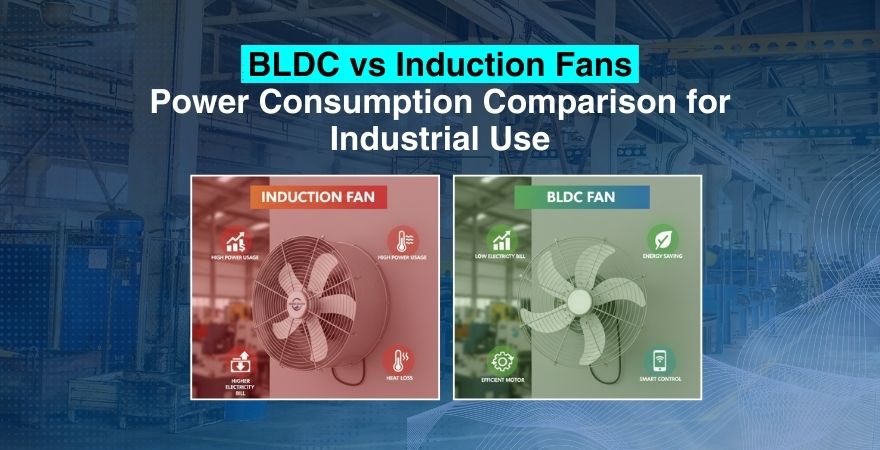

In induction motor fans, a significant portion of electrical energy is lost as heat. Mechanical friction, electrical losses, and inefficient motor design all contribute to higher power consumption. As operating hours increase, internal temperatures rise, further reducing efficiency.

This means that even if airflow remains constant, the fan draws more power over time to maintain performance. The result is a higher electricity bill with no visible improvement in comfort or productivity.

In a typical induction fan:

- Copper (I²R) losses: Current through coils heats them up.

- Iron losses: Changing magnetic fields in the stator/rotor cores dissipate energy.

- Mechanical losses: Bearings and air drag create frictional drag.

- Additional losses: As the motor heats, insulation resistance changes, further lowering efficiency.

The result? An induction fan must draw more watts to maintain the same airflow over time. In other words, even if CFM/CMM is constant, the power draw creeps up as the motor heats and wears. By the end of a long shift, an induction fan can consume well above its rated power simply to sustain performance.

BLDC Fans: How Technology Cuts Waste

BLDC fans address these losses at their core. They use permanent magnets and electronic commutation to drive the motor, eliminating brushes and gearboxes. Key advantages include:

- Direct Conversion: BLDC controllers feed precise pulses of DC current to the coils. This means less wasted energy compared to AC induction.

- No Brushes: Without carbon brushes (which cause friction and spark), BLDC motors avoid brush-gear losses.

- Permanent Magnets: BLDC rotors have permanent magnets, so there’s no need to induce current in rotor bars (as in an AC motor). This greatly reduces I²R losses and heat.

- Electronic Speed Control: The built-in driver optimizes torque at every RPM, avoiding the inefficiencies of capacitor-run AC fans.

BLDC fans work differently. Electronic commutation allows power to be converted more directly into airflow, reducing losses and minimising heat generation. Less wasted energy means lower power draw for the same output.

Why Long Operating Hours Magnify the Difference

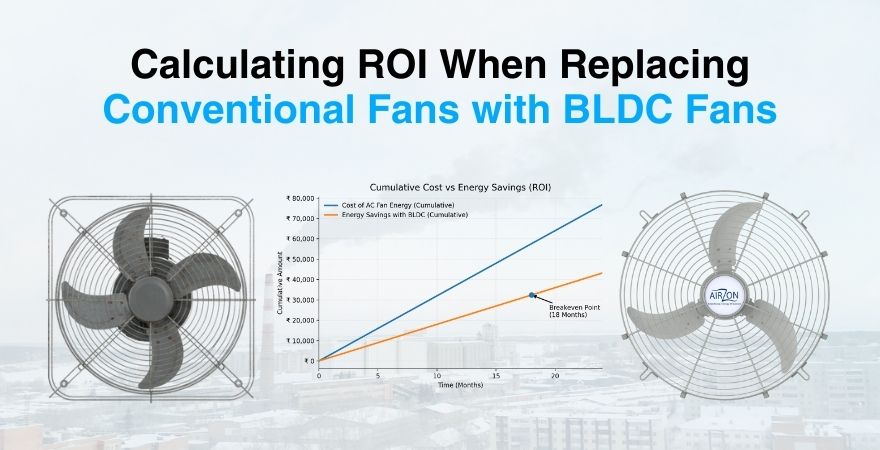

In industrial and commercial environments, fans often run for 12 to 16 hours a day, sometimes longer. Over such extended operation, small efficiency gaps become large cost differences.

- For example, saving just 50 watts (0.05 kW) every hour equals 0.6 kWh per 12-hour day, or ~220 kWh/month per fan. In large facilities, multiply that by dozens of fans and hundreds of days, and the savings soar.

- Airzon (an Indian BLDC brand) cites a ceiling fan example: 10h/day use at ₹7/kWh yields ~₹1,000 annual savings per fan by dropping from 75W to 30W

In practical terms, if two identical-airflow fans run all day, the lower-efficiency fan can rack up tens of thousands more kWh per year. The original blog noted a 40–50W gap felt insignificant in an hour, but compounds into huge annual bills. What doesn’t show up on the first day’s comfort bill becomes painfully clear after months of utility statements.

Design and Materials Matter

Motor technology isn’t the only factor. Construction quality and material choice play a critical role in energy performance over time.

Fans with plastic components are more susceptible to deformation and heat-related fatigue. As components wear, efficiency drops, vibrations increase, and power consumption rises further.

Industrial-grade, all-metal construction maintains structural stability under prolonged heat and load. When paired with BLDC technology, this ensures that efficiency is preserved not just on paper, but throughout the fan’s service life.

Airzon’s Perspective on True Efficiency

At Airzon, efficiency is measured not only by airflow, but by airflow per watt over long operating hours.

Airzon’s BLDC industrial fans are engineered with:

- Energy-efficient BLDC motors optimised for continuous use

- Plastic-free, all-metal construction for durability

- Lower internal heat generation, reducing efficiency loss

- Stable performance under voltage fluctuations

The result is consistent airflow delivered with significantly lower power consumption day after day.

What the Energy Bill Reveals Over Time

The difference between fans becomes most evident over months of operation. Facilities using efficient BLDC fans experience:

- Lower electricity bills

- Reduced heat-related maintenance

- Longer service life

- Predictable performance

Those relying on conventional induction fans often face rising costs without understanding why.

Conclusion

Two fans can look the same, feel the same, and move the same air yet cost very different amounts to operate. The difference lies in motor efficiency, internal heat management, and design integrity.

For organisations focused on long-term efficiency rather than short-term purchase price, understanding this distinction is essential. When airflow is equal, efficiency decides the bill.