In most industrial and commercial spaces, fans don’t work in short bursts. They run through long shifts, extended hours, and sometimes around the clock. Yet, very few people stop to think about what actually happens inside a fan that runs for 16 hours a day, day after day.

From the outside, everything looks normal. The blades spin, the airflow feels steady, and operations continue uninterrupted. Internally, however, the story can be very different.

Hour 1–4: Business as Usual

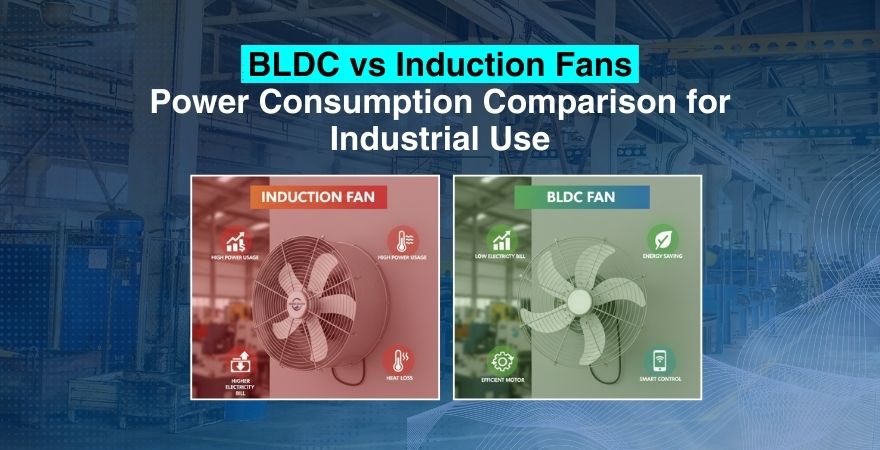

When a fan starts its day, performance is usually at its best. Motors are cool, components are stable, and airflow is efficient. In conventional induction fans, electrical energy is already being lost as heat, but early in the cycle, this isn’t noticeable.

BLDC fans, by contrast, convert a higher percentage of electrical input into useful airflow. Less energy is wasted, and less heat is generated inside the motor.

Hour 5–8: Heat Begins to Accumulate

As operating hours increase, internal heat starts to build up—especially in induction motor fans. This heat doesn’t just disappear. It stresses windings, affects bearings, and slowly reduces efficiency.

At this stage, fans may still appear to work fine, but internally, energy losses increase. The motor works harder to maintain speed, drawing more power for the same airflow.

BLDC motors behave differently. Because electronic commutation eliminates many mechanical losses, internal temperatures remain significantly lower, even during extended operation.

Hour 9–12: Efficiency Starts to Drop

This is where long-hour operation begins to matter. In induction fans, prolonged heat exposure accelerates wear. Bearings experience more friction, insulation ages faster, and vibrations can increase. None of this causes immediate failure—but it quietly reduces lifespan.

BLDC fans are designed for continuous duty. Lower heat generation means components remain within safe operating limits, helping maintain consistent airflow and stable power consumption.

Hour 13–16: The Hidden Cost of Design Choices

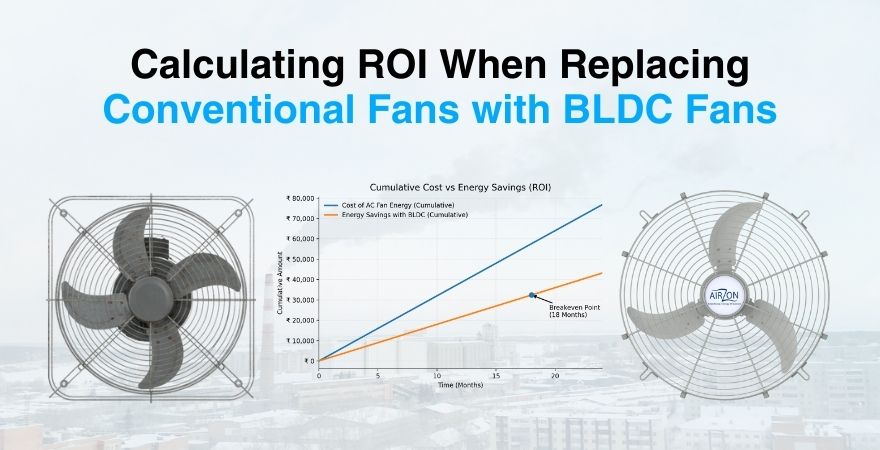

By the end of a long operating day, the difference between fan technologies becomes clear. Induction fans may consume more energy than their rated values due to heat-related inefficiencies. Over months and years, this leads to higher electricity bills, frequent maintenance, and unexpected downtime.

Material choice also plays a critical role. Fans with plastic components are more vulnerable to deformation, fatigue, and long-term failure in high-temperature environments. Industrial-grade, all-metal construction withstands prolonged thermal stress far better.

This is where design decisions made at the manufacturing stage directly affect real-world performance.

Why Long Operating Hours Demand Smarter Technology

In facilities where fans run 16 hours a day or more, efficiency isn’t just about energy savings it’s about reliability. Reduced maintenance interruptions, predictable performance, and longer service life all contribute to smoother operations.

BLDC technology addresses these needs at the core. By reducing internal heat, stabilising speed under voltage fluctuations, and improving energy conversion, BLDC fans are better suited for long-hour industrial use.

When combined with plastic-free, metal construction, the result is a fan that doesn’t just survive long shifts but performs consistently through them.

The Bigger Picture

The real question isn’t how long a fan can run. It’s how well it performs while doing so.

For industries focused on long-term efficiency and operational stability, understanding what happens inside a fan during extended operation changes how cooling solutions are evaluated. The difference isn’t always visible on day one—but over thousands of hours, it becomes impossible to ignore.